Say you are browsing the internet and see a really sweet

Lindsey Lohan bobble-head to add to your secret collection. Well, instead of

waiting a week for it to arrive by mail or walking into the mall shamefully,

you just click print. In less than 10 minutes you could be admiring your new

guilty pleasure, or telling Lindsey all about your day with her listening

intently (bobble-bobble), made possible by your brand new 3D printer! While

this might be a niche (and weird) example, there are many practical uses for 3D

printing, but let’s first go over the basic idea.

The concept of 3D printing is quite simple being very

similar to a typical 2D, inkjet printer you use at home or work. Instead of

having cartridges of blank and colored ink, a 3D printer takes a material

(typically plastic) and sets a micro blob of liquid material onto the work

surface. This quickly hardens, and then another blob is set, again and again. With

the blobs building onto each other, like little building blocks, until you have

whatever you programmed the 3D printer to make. These designs are usually from

a Computer Aided Drafting program, and there are many available

online for free or a small price. Currently a scenario like the Lindsey Lohan

bobble-head is missing a few things, there are no large commercial websites

where you can purchase patented goods (like an iconic celebrity bobble-head)

and most 3D printers can only use one type plastic a time (you would just have

to spend some extra, quality time with a set of paints and your new BFF).

|

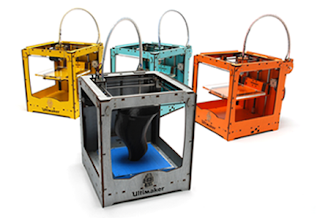

| From the Ultimaker Website |

One product, called the Complete Ultimaker DIY-Kit, was recently

brought to the market by a small Dutch company, Ultimaker, in May of 2011.

While there are many different 3D printer companies out there, the Ultimaker

stands out because of its price, with a 21x21x22 cm potential build volume (the

largest volume part the machine can build) for about 1600 USD. This is one of

lowest priced printers out there, and this draw is only enhanced by its open-source

software and hardware, meaning the company encourages changes to its software

and hardware to suit its customers’ needs.

|

| Thor from Starcraft II, example from the Ultimaker Website |

The drawbacks are that you need to have some technical

background (or be willing to spend a frustrating weekend) to assemble the machine

from its major components (DIY stands for Do-It-Yourself, so their target

audience enjoys this sort of thing). Also, it can only use plastic and in this,

one color of plastic at a time. While more expensive models can print with a

few different colors of plastic and some can use multiple materials, as with

anything the price goes up more features. This and that most printers can only

be used for relatively small objects, are the areas that could be greatly

improved upon in the future.

Some enticing technical specifications, for the enthusiast,

are its printing precision, in the Z axis it can lay down material around 0.1

mm, but it is best for features to be at least 0.5 mm due to structural

considerations (you don’t want your new plastic toy to fall apart). It is

actually more precise in the vertical direction (y-axis), being able to create

layers of about 20 micrometers (less than 0.0008 inches). The website says that

when designing the part, taking this into consideration will allow you to

decide the best orientation for printing. For more tech specs, you can see

their website here and the FAQ.

While I used the example of a niche bobble-head, 3D printing

is used extensively in engineering research, which can be considered a part of

the process of rapid prototyping. This process allows engineers to quickly

build a part to test the design. Consider a mechanical engineer designing and

building intricate part for an existing engine and he or she will be using an

expensive composite material to make it. Within an hour or two a 3D printer

could create a plastic version that then could test the shape and size of the

current design within engine. If it fits, then the design could be shipped off

to the manufacturer, or the design could be quickly modified, all potentially

saving time and money.

3D printing is not just for engineers and researchers. A 3D printer in the home could allow you to build multiple copies of door handles, little horses for party favors, multiple pieces to build a replica of the Eiffel Tower for a school project, etc. If someone could design it on the computer, and it could fit within the build platform, a 3D printer could probably build it (you can download designs that others have made if you are not confident in your CAD skills).

The future is full of exciting innovations, many are only in the stages of inception and some of the game-changers are still waiting discovery. One invention that changed the way we view and interact with society and world was the personal computer. Most people know that it took a few years for the computer to gain wide commercialization with some starting at 2000 USD in the 1980s, but once they reached a certain point, the revolution began. What is the next upheaval? Many people point to the emerging tech of 3D printers. A word of caution; if you know a hoarder, do not get them one for Christmas.

The future is full of exciting innovations, many are only in the stages of inception and some of the game-changers are still waiting discovery. One invention that changed the way we view and interact with society and world was the personal computer. Most people know that it took a few years for the computer to gain wide commercialization with some starting at 2000 USD in the 1980s, but once they reached a certain point, the revolution began. What is the next upheaval? Many people point to the emerging tech of 3D printers. A word of caution; if you know a hoarder, do not get them one for Christmas.

|

| Yoda made by Screal |

I forgot to add a bit; the revolution idea of 3D printing focuses on the increased access of both computers to design and the printers to make these designs real. In some ways it could level the playing field of design and manufacturing, opening it up for many many new people instead of just large corporations. Of course there will be many legal issues - see 3D printing a gun in the news - and copyright/patent violations. Who knows how it will turn out?

ReplyDeleteNice read. I like the examples of uses and the technical specifications that you included. 3D printers seem pretty neat. I think it's especially cool that you can use a 3D printer to make parts for another 3D printer.

ReplyDeleteThis was an interesting topic. Good content and extent of review and the attributes of the product. I wondered about the price at first, but maybe they dont include that on the site either. Nice job

ReplyDeleteI liked all the technical language you use when describing the 3D printer. I like how you included some of the pros and cons when it comes to using the 3D printer. Nice work.

ReplyDeleteGreat Post!! I knew these things were real but I have never seen one before. You do a great job aproaching you subject and a great use of technical language so anyone can understant what you are talking about.

ReplyDelete